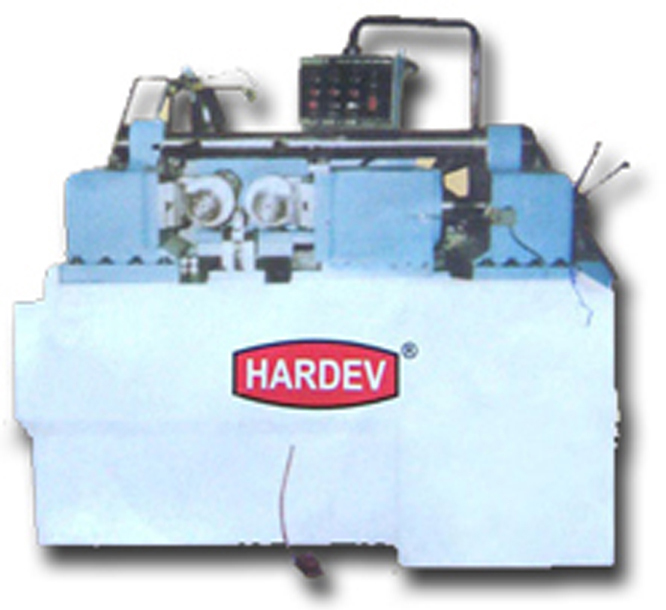

Flat Die Thread Rolling Machines

Our flat die thread rolling machines allow the production of large and small batches of all kinds of threads that can be cold formed, in the most economical way. The normal basic data stated in the table for each machine type are not limiting values. Practical tests in the areas of manufacturing techniques and material behavior extend performance limits of our machines further and further.

Our developments are being determined by and over increasing and move accurate knowledge which enable us to conceive tailor made designs for SPECIALS APPLICATIONS, MATERIAL SPECIALTIES, SPECIFIC DIMENSIONS & DIE-SHAPES.

| SPECIFICATION OF FLAT DIE THREAD ROLLING MACHINES | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| Type of Machines. | A | B | C | D | E | F | G | ||

| Min. Max. Dia Can Be Rolled | 1/16" 1/4" | 1/8"-1/2" | 1/8"-1/2" | 1/4"-5/8" | 1/4"-3/4" | 1/4"-7/8" | 3/8"-1" | ||

| Maximum Length of thread | 2" | 21/2" | 3" | 3" | 4" | 4" | 4" | ||

| Dimension of Fixed die | 3"X2"X1" | 5"X21/2X1" | 5"X3"X1" | 6"X3"X1" | 6"X4"X1" | 7"X4"X1" | 8"X4"X11/2" | ||

| Dimension of moving die |

4"X2"X1" | 6"X21/2"X1" | 6"X3"X1" | 7"X3"X1" | 7"X4"X1" | 8"X4"X1" | 9"X4"X11/2" | ||

| Production In Pieces per minute | 80 | 60 | 60 | 50 | 30 | 30 | 20 | ||

| Power required in H.P | 2 | 3 | 5 | 7.5 | 10 | 15 | 20 | ||

| 7 | 500 | 200/8 | 700/28 | 75/3 | 700/28 | 800 - 250 | 40/960 | ||

Tie Rod Thread Rolling Machines

Powerful Construction Permits deep forming of Threads, Worms, Serrations, Knurls, Rigidity & Simplicity :grade1 casted hardened and duly scrapped slide, also the easy adjustment of machines as well as tooling enables an unskilled labourer to operate the machine. Machine is very much suitable for mass production and best surface finishes.

Hydraulic Thread Rolling Machines (Three Roll Type)

The 3 rollers H-3R rolling machine operate hydraulically. The simultaneously and concentricity of three forces at 120 o assure stability of the work piece during the rolling and as a consequence the maximum geometrical precision of the work piece.

The elimination of the support blade consents a better finishing of the piece and execution of perticularly delicate profiles. The machine is suitable for rolling pipes, lapping work, threading with a high class precision and for mass production of scaffolding pipe jacks screw etc.

| THREE ROLL TYPE | H3R-50 | H3R-75 | |||

| Work Range | Outside Diameter | 15-50 Mm | 5/8"-2" | 25 -75 Mm | 1"- 3" |

| Thread Length In Feed | 50 Mm | 2" | 75 Mm | 3" | |

| Thread Length Through Feed | Indefinite | Indefinite | |||

| Max. Thread Pitch | 0.8 - 3 Mm | 32 - 8 TPI | 0.8 - 6 Mm | 32 - 4 TPI | |

| Roll Dies | Max In Side Dia | 140 | 160 | ||

| Max Out Side Dia | 40 | 54 | |||

| Max. Width | 50 | 80 | |||

| Motor 3 Phase AC | For Roll Spindle | 5 H.P. | 10 H.P. | ||

| For Hydraulic System | 3 H.P. | 5 H.P. | |||